Why MotionMark?

Stop Over or Under Greasing your Equipment

Daily and weekly equipment maintenance is essential for maintaining the service life and reliability of your machinery. The problem with these intervals is that many times equipment is not used all day every day throughout the year and one of two things happen:

Equipment is still greased every time is it used - even if only used for an hour or two. This means that over 12 machine hours, it could get lubricated 5-10 times! This is a waste of materials and time that doesn’t prolong the life of your equipment.

Equipment not greased regularly - This is worse than above. Employees assume that since they are only using the machine for a couple of hours that it is not necessary to grease since the person who used it before likely did. Once multiple employees start making this assumption, the equipment in fact does not ever get maintained until breakdowns occur.

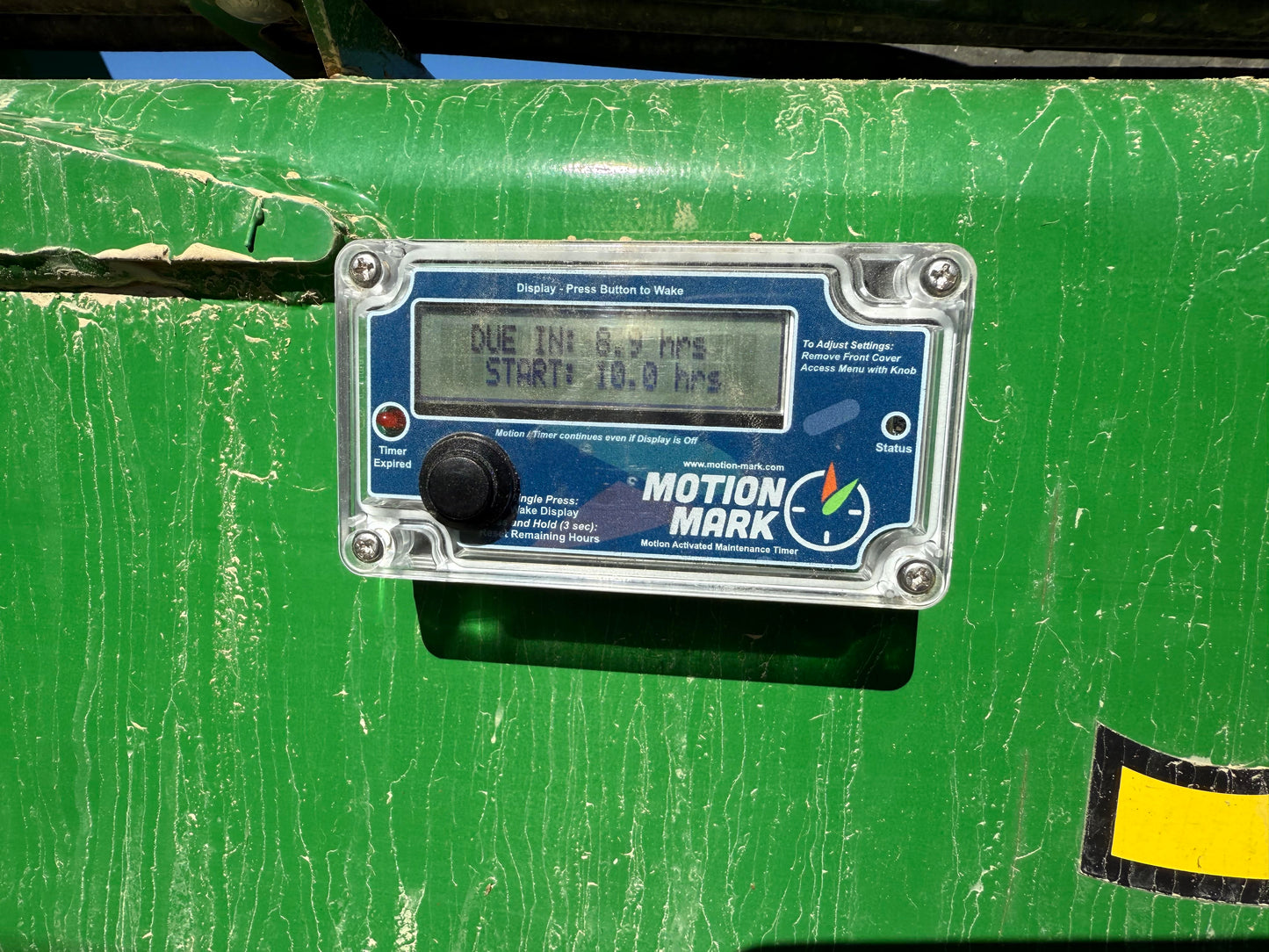

Motion Mark was developed as a solution to this problem. Now regular maintenance can be easily tracked without complicated work-orders and processes. Just grease the machine if the light is flashing prior to using it and reset the motion activated timer. The timer is adjustable from 1 hours to 999 hours to accommodate different maintenance intervals.

| Grease Every Day | Motion Mark | |

| Advantages |

No upfront cost Works well for consistently used machines |

Easy to see when maintenance is due Ensures proper lubrication regardless of use frequency See at a glance if machine is being maintained |

| Disadvantages |

Over-greasing wastes time and money Under-greasing causes machine wear Not clear if maintenance is being performed. |

Upfront cost of Timer Battery replacement 1x per year |

MotionMark

Motion Activated Maintenance Timer

Share